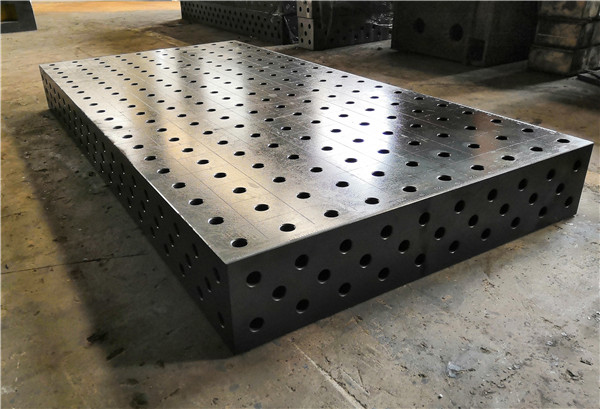

méja las Nitrided

tabel las nitrided kalawan karasa High, euweuh karat, nyegah las slag nempel kana beungeut méja

Tabel ukuran di handap ieu aya di stock

D 28 méja las 3D

| 4000x2000x200mm | 3000x2000x200mm |

| 3000x1500x200mm | 2000x1500x200mm |

| 2400 x 1200 x 200 mm | 2000x1000x200mm |

| 1500 x 1000 x 200 mm | 1200 x 1000 x 200 mm |

| 1000 x 1000 x 200 mm | 5000x2000x200mm |

| 4000x2500x200mm | 3000x2500x200mm |

| 4000x1500x200mm | 4000x1000x200mm |

| 2500 x 1500 x 200 mm | 3000x1000x200mm |

| 2500 x 1000 x 200 mm | 2000x2000x200mm |

| 1500 x 1500 x 200 mm | 1200 x 1200 x 200 mm |

D16 méja las

| 2000x1500x150mm | 2000x1000x150mm |

| 2400x1200x150mm | 1500x1000x150mm |

| 1200x1000x150mm | 1000x1000x150mm |

méja las 2D

| 2000x1500mm | 2000x1000mm |

| 2400x1200mm | 1500x1000mm |

| 1200x1000mm | 1000x1000mm |

| 1200x800mm | 1200x1200mm |

Urang bisa ngaropea tabel las tina ukuran béda nurutkeun sasuai ka nu Anjeun

Méja las 3D: lima permukaan kerja anu tiasa dipasang sapotong tempatna.Ogé bisa diperpanjang via salah sahiji lima surfaces gawé na.

• Pikeun bahan na dibagi kana:Méja las bajas jeung beusi tuangMéja las

• Pikeun diaméterna liang dibagi kana: runtuyan D28, runtuyan D22 jeung runtuyan D16.

Diagonal Grid: D28 na D22 nyaeta 100 * 100mm;D16 nyaeta 50 * 50mm

Ngarojong: suku, pigura baja nurutkeun sarat.

3D Welding Tables And Fixtures komponén bisa dilengkepan sanggeus anjeun milih:

1, Alat pikeun ngadukung: kasus kubus U-Shaped, kasus kubus L ngawangun, Sudut ngadukung, sareng Angle gauge

2, suku cadang pikeun Locating:

3, Pakakas pikeun clamping sarta ngaropéa

4, suku cadang pikeun ngonci sapotong kerja

5, Alat Bantu

Tables las ModularFitur

• Ampir kabéh workpiece bisa dibenerkeun persis dina titik nu tangtu atawa surfaces kalawan locating sapotong, adapting sapotong, fastening sapotong jeung ngarojong sapotong, dina prosés assembling atanapi las.

• dimensi imprecise of workpiece bisa disaluyukeun salila prosés kerja awal.

• Ieu gampang ngagunakeun bagian aya di bengkel pikeun niru assembly workpiece via CAD.

Méja fabrikasi las kerja ékonomis

• Simpen loba ongkos tinimbang reserving loba fixtures tradisional pajeulit jeung mahal

• Manglaku ka sagala rupa kaayaan gawé tanpa merlukeun modifikasi nanaon

• Gampang tur aman beroperasi.

FleksibelMéja las 3d

• Cukup padet pikeun nanggung beban anu beurat pisan.

• Lima surfaces, liang biasa na garis grid (euweuh liang condong atawa alur T ngawangun)

• Sagala workpiece bisa dibereskeun sarta clamped dina tabel kalawan locating pin

• tabel las 3D bisa numbu babarengan ngalawan salah sahiji lima surfaces na.

Méja las tepat

• Ampir kabéh workpiece bisa dibenerkeun persis dina titik nu tangtu atawa surfaces kalawan locating sapotong, adapting sapotong, fastening sapotong jeung ngarojong sapotong, dina prosés assembling atawa las

• dimensi imprecise of workpiece bisa disaluyukeun salila prosés kerja awal.